As the core moving part of the hydraulic cylinder, the maintenance and repair of the hydraulic cylinder rod is a complex technical work. The work involves fault diagnosis, material selection, and the selection of maintenance technology. Whether it is a senior engineer in the hydraulic field or a novice in the industry, you need to master the maintenance method.

This article will deeply analyze the chrome plated rod (hydraulic cylinder rod) and provide maintenance technology based on practical experience. Thereby improving the operating reliability of the equipment and reducing the downtime. Effectively control the operating costs for users.

Why Hydraulic Cylinder Rods So Important?

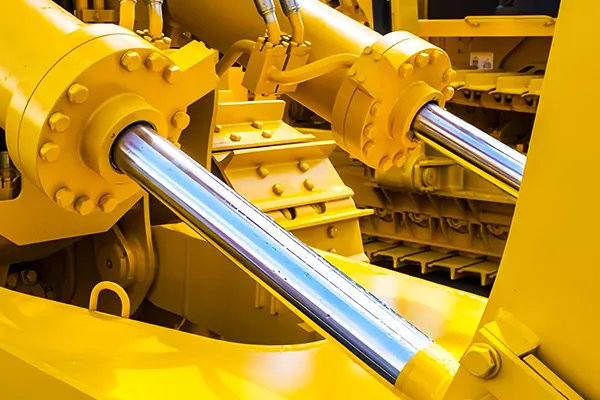

Hydraulic cylinder rod is a key component of hydraulic cylinder, which is responsible for converting hydraulic energy into mechanical energy. In many application fields such as engineering machinery (such as excavators, loaders, cranes), agricultural equipment (such as combine harvesters, tractors) and industrial pressure equipment. The linear motion force of chrome plated bar converts fluid pressure into push and pull force output. Thus completing the lifting and pushing tasks of heavy equipment.

The mechanical properties of hard chrome rod directly determine the overall quality of the hydraulic system. The mechanical properties of hydraulic cylinder rod include: tensile strength, surface hardness, dimensional accuracy and corrosion resistance. The use of high-quality materials and ultra-high surface treatment technology can reduce seal wear and prevent hydraulic oil leakage.

Choose a suitable piston rod to ensure the normal operation of the system. For example: choose a matching material grade (such as 45# steel, 40Cr), a reasonable treatment process and appropriate surface protection.

How to Identify Common Damage in Hydraulic Cylinder Rods?

The first is surface damage. It manifests as axial scratches, annular grooves caused by abnormal wear of the seal, and local depressions. These surface defects will damage the fit between the rod and the seal, resulting in hydraulic oil leakage, system pressure drop and increased energy consumption.

The second is deformation and bending of chrome bar. It manifests as the straightness does not meet the requirements. It may usually be caused by overload, misaligned installation or unexpected impact load. Deformed piston rods with hard chrome treatment on the surface will cause abnormal wear of the guide sleeve and seal.

Also pay attention to the sealing system. When there is a continuous oil film or dripping phenomenon, it means that the sealing components (including the main seal, dust ring, guide ring, etc.) have been worn. It’s necessary to check and repair the sealing system in time. To avoid contaminating the hydraulic oil and damaging the rod surface.

| Damage Type | Description | Potential Consequences |

|---|---|---|

| Scratches/Pitting | Surface imperfections on the rod | Seal damage, leaks, reduced efficiency |

| Bending | Curvature or misalignment of the rod | Impeded operation, strain on components, premature wear |

| Seal/Gland Issues | Leaks around the rod, worn seals | Fluid loss, contamination, system failure |

| Corrosion | Rust or other forms of chemical degradation of the rod’s surface | Weakening of the rod, contamination of hydraulic fluid |

What’s the Difference Between Tie-Rod and Welded Hydraulic Cylinders?

There are two main types of hydraulic cylinder structural design. Tie-rod type hydraulic cylinder and welded hydraulic cylinder.

Tie-rod hydraulic cylinder uses prestressed tie rods made of high-strength alloy steel. Usually, components such as end caps, cylinder barrels and pistons are connected as a whole. Because each component can be replaced independently, it is easy to disassemble and maintain on site. Tie rod type is widely used in industrial equipment such as injection molding machines and die casting machines that require regular maintenance.

Welded cylinders have the end caps welded directly to the cylinder barrel. This makes the cylinder more compact and usually has a higher pressure rating. Repairs are difficult due to the close proximity of the welds cut during assembly; each tie rod or weld configuration has its advantages and disadvantages depending on specific factors such as pressure requirements (such as controls used by air filters) and maintenance needs.

| Feature | Tie-Rod Cylinders | Welded Cylinders |

|---|---|---|

| Construction | Cylinder barrel held together by threaded steel tie rods | End caps welded directly to the cylinder barrel |

| Disassembly | Easy | Difficult, requires cutting welds |

| Maintenance | Easier, components can be replaced individually | More challenging, often requires complete cylinder replacement |

| Pressure Rating | Generally lower | Generally higher |

| Cost | Typically less expensive | Can be more expensive due to complex manufacturing |

| Applications | Industrial machinery, mobile equipment, agriculture | High-pressure applications, heavy-duty construction equipment |

Choosing the Right Material: 1045 Steel vs. Chrome Plated Options

The performance and durability of hydraulic cylinder rod are significantly affected by the materials used. 1045 steel is typically a medium carbon steel that offers a good balance of strength, flexibility, and cost-effectiveness due to its ability to be heat treated to increase hardness and wear resistance.

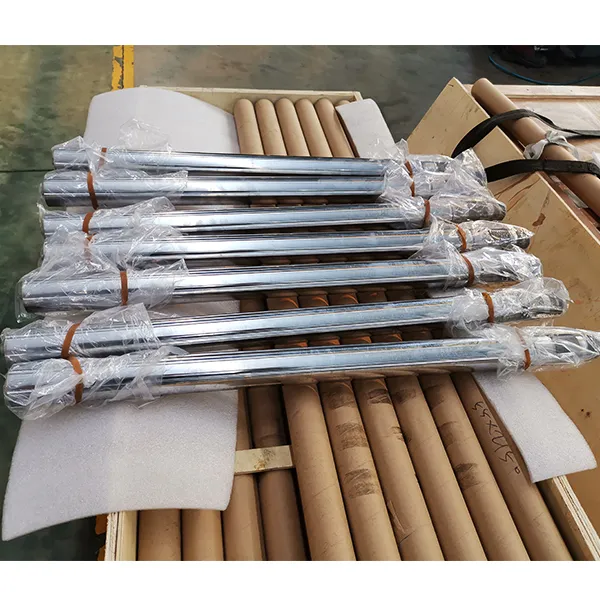

The hard chrome layer on the chrome plated rod has strong corrosion resistance and a smoother surface. The hard chrome layer is relatively hard, seals joints with a low coefficient of friction, is highly stable in contact with heat or low temperatures, and provides a longer service life in applications where wear is unavoidable.

- 1045 Carbon Structural Steel:

- Tensile strength ≥585MPa

- Heat treatment, reaching hardness

- Meet the application of most medium and high pressure hydraulic systems.

- Chrome Plated:

- Surface hard chrome layer thickness: 0.03-0.05mm

- Microhardness can reach 800-1200HV

- Can pass neutral salt spray test level 9 200 hours

- Surface roughness controlled at Ra0.1~0.3μm

- Suitable for harsh working conditions such as high humidity and high pollution

- Induction Hardened:

- Induction heating technology, 2-4mm deep hardened layer on the surface

- Excellent wear resistance and impact resistance

- Suitable for heavy loads such as mining machinery and engineering machinery

How to Calculate Stroke, Bore, and PSI for Your Cylinder Rod?

To determine the correct stroke, you must know what amount of travel is required for your application. The bore size and force involved are closely related to how much force there will be a given pressure on any surface area (i.e. if it was necessary). In extreme temperature conditions (such as below -20°C or above 80°C), the effect of changes in hydraulic oil viscosity on system pressure must be considered. Too high a rated pressure may cause difficulties in starting at low temperatures, while too low a pressure setting will reduce system efficiency and increase operating costs.

Use the formula to calculate the force output by the hydraulic cylinder:

Output force F (kN) = working pressure P (MPa) × effective area A (cm²)

Where the effective area of the piston is calculated as:

A = π × (D/2)² (D is the piston diameter, unit: cm)

When the calculated result is less than 50% of the rated output force of the system, it is recommended to re-evaluate the cylinder diameter selection. To ensure sufficient force reserve coefficient (usually 1.2-1.5 times) to avoid system failure due to instantaneous overload.

Click Here, Find the Best Hydraulic Cylinders Rod to Match Your Needs.

Conclusion

To remember about hydraulic cylinder rod repair and maintenance are as follows:

- In industrial fields such as engineering machinery, metallurgical equipment, and marine systems. the linear motion accuracy of the piston rod determines the operating performance of the equipment.

- Regular inspection and maintenance are crucial to prevent damage and extend the lifespan of your hydraulic equipment.

- Damage caused by scratches, dents, bends and sealing problems are the most common types of damage.

- Tie-rod and welded cylinders offer different advantages and disadvantages.

- In certain cases, the rod can be straightened to a bent shape, but replacement may need replacing.

- The production of high quality hydraulic cylinder rods is dependent on various factors, such as material quality and dimensions.

For more information on products or further assistance, feel free to Contact Us. Click Here to exploring more about Honed Tubes>, Seamless Precision Steel Tubes>.

Hard Chrome Rod

Meet The Production Needs of Manufacturers. Increase Your Net Profit.