DIN2391 precision seamless steel tube are widely used in hydraulic and pneumatic systems in the fields of engineering and manufacturing. Precision seamless steel pipe are the backbone to ensure efficiency, safety and life. In this article, we will explore what makes DIN 2391 cold drawn precision seamless tube the first choice for hydraulic systems and why they are so important to your project.

What is DIN Precision Seamless Steel Tube?

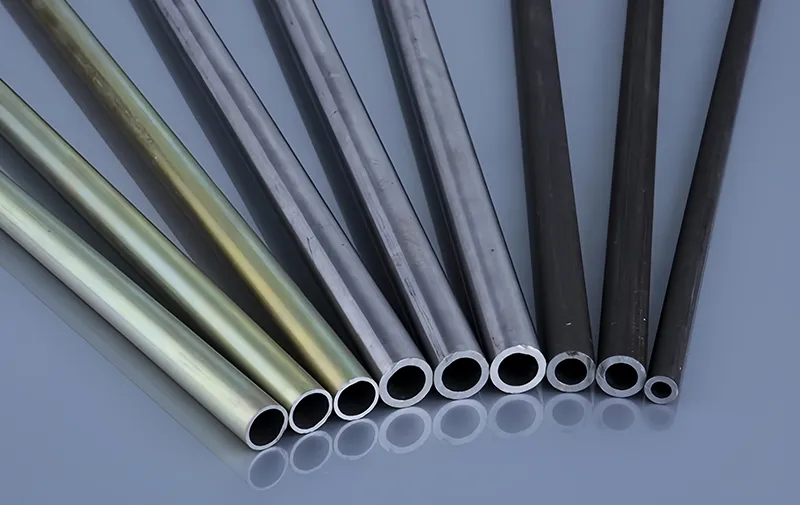

DIN 2391 seamless precision steel tube is a high-quality material used in hydraulic and pneumatic systems. Seamless steel tube is manufactured to exacting tolerances and specifications. Unlike welded pipes, seamless tubing are seamless. The tubes are made of raw steel for strength and durability.

Cold drawn steel tubes are widely used in industries with high requirements on pipe quality due to their high precision and no welds, such as pneumatic and hydraulic systems, and automobile manufacturing.

Why Precision is Matters

Precision ensures that carbon steel tube meet strict dimensional and tolerance requirements. In hydraulic and pneumatic systems, DIN standard cold drawn seamless pipes must ensure the accuracy of the inner diameter. This can effectively avoid leakage problems and ensure the efficiency of fluid flow.

Accurate dimensions also improve the mechanical properties of the pipe. High precision pipes have excellent bending and torsional strength.

The high precision of steel tube ensures that pipes meet the exact dimensions and tolerances of the required industries. DIN cold drawn seamless tubes have precise inner diameters, making them better for hydraulic and pneumatic systems. This prevents leaks and ensures efficient fluid flow.

Seamless Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.

What is the Process of Precision Steel pipe?

Carbon steel pipe manufacturing process mainly includes cold drawing or cold rolling.

- Cold-Drawn is the deformation of steel billet by stretching, which is usually used to produce precision steel tube. In this process, the billet is pulled through a die to reduce its diameter and wall thickness. So that the size of pipe can be controlled and the surface finish can be improved.

- Cold Rolling: The process of pressing strip steel into thin sheets or other shapes. For the production of steel pipes, cold rolling can be used for the processing of strip steel, and it can also indirectly affect the subsequent forming of the pipe. Compared with hot-rolled steel pipes, cold-rolled seamless precision steel pipes have material mechanical properties and gloss.

Both processes can improve the precision and consistency of carbon steel pipes, strictly complying with standards such as DIN 2391 and EN 10305-1.

What Is DIN 2391 Standard?

DIN 2391 standard is a German custom standard. It mainly puts forward clear requirements for high-precision seamless steel tubes in the fields of machinery and general engineering. The standard specifies key indicators such as the size and tolerance range, surface quality and mechanical properties of the pipe in detail. Complying with DIN 2391 standard ensures that the tube can operate stably in high-stress environments.

Applications of Precision Steel Tubes

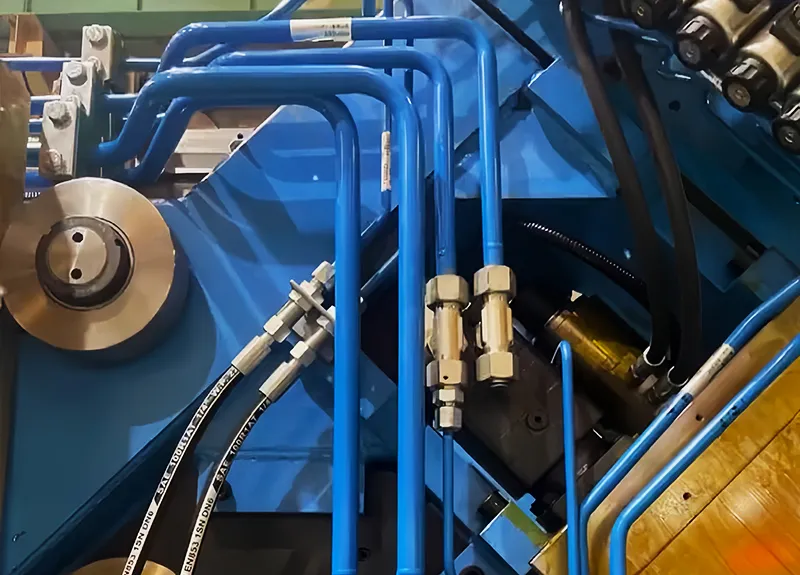

Precision seamless steel tubes are important components for the efficient operation of hydraulic systems. These pipes are mainly used for:

- Transportation of hydraulic fluid to ensure no leakage.

- Maintaining a constant pressure level

- Stable performance can be maintained under high pressure.

Hydraulic systems require extremely high precision, and any slight deviation may cause system failure or reduced operating efficiency.

For more information, check our seamless precision steel hydraulic tube page>.

Benefits of Using High Precision Seamless Tubing

precision cold drawn steel tube have higher torsional strength compared with solid steel pipes.

precision steel seamless tubes are lightweight and ideal for hydraulic and pneumatic line.

High precision and high pressure resistance make them suitable for high pressure environments

Steel tubes require less maintenance and have a long service life, which improves cost-effectiveness.

For those interested in high-quality products, visit our hydraulic cylinder honed tube section>.

How to Choose the Right Steel Grade?

Choosing the right steel grade is key to ensuring it meets the needs of a specific application. The following are reference directions:

First, you need to analyze the basic properties of the material, such as whether the tensile strength, elongation and impact resistance match the actual working conditions. If the application environment has corrosive media or extreme temperature and humidity, alloy materials with oxidation resistance, acid and alkali resistance should be given priority.

Industry standards are an important basis. For example, in the field of hydraulic transmission or precision machinery, materials can be selected according to specifications such as ASTM A519 and EN1305-4. Taking DIN 2391 standard carbon steel pipe as an example, its strict dimensional tolerance and surface treatment process can not only improve transmission efficiency but also reduce maintenance frequency in industrial equipment manufacturing, especially suitable for long-term high-load operation conditions.

Frequently Asked Questions

Q1: What is the difference between seamless and welded tubes?

A: Seamless steel tubes are manufactured by hot perforation of billets combined with hot and cold deformation processes, without seams. Welded tubes are manufactured by cold bending of strips and then joining with energy beams, with welds.

Q2: Why use precision tubes in hydraulic systems?

A: The outer diameter tolerance of hydraulic precision cold-drawn tubes can reach ±0.08mm. The roughness Ra≤0.4μm, which reduces the fluid friction coefficient to 0.008.

Q3: Are precision seamless pipes more expensive?

A: Yes, Precision tube billets require the use of VOD refined steel ingots, resulting in higher raw material costs than ordinary tubes. Three intermediate annealings are inserted between the cold rolling/cold drawing processes, increasing the unit energy consumption cost to 2.7 times that of conventional cold drawn tubes. The proportion of quality control costs is also high.

Conclusion:

seamless precision steel tubes widely used in machinery manufacturing, industrial equipment, construction, heavy truck and other industries.

For high quality steel tubes and expert advice, browse Global seamless steel tube manufacturer offerings>. For more information, feel free to contact Global Steel Tube for expert advice.

Seamless Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.