In the field of industrial and hydraulic systems, EN10305-1 precision seamless steel tubes are essential raw materials for lines. EN 10305 seamless precision steel tube is known for its high strength, durability and high precision. These steel tubes are designed in accordance with European standards to meet the stringent requirements of industries such as hydraulics, automotive and precision engineering.

What is EN 10305-1 Standard?

EN 10305-1 is a European standard that specifies the technical delivery conditions for cold drawn seamless steel tubes used in hydraulic and pneumatic systems. It mainly includes requirements for dimensions, tolerances, material properties, and testing procedures. The EN 10305-1 standard ensures that these precision seamless steel pipes meet strict quality standards, making seamless cold drawn tubes suitable for applications where precision, reliability, and performance are crucial.

EN10305 standard covers various steel grades, including E235, E355, etc., each with different mechanical properties. When you see cold drawn seamless precision tube marked with EN 10305-1, you can be confident that the pipe has undergone strict quality control processes. For example, the steel grade name represents the specific chemical composition and mechanical properties of the steel pipe, ensuring consistency and reliability in demanding applications. For precision cold drawn steel tube, the EN 10305-1 standard is the most important standard.

How Are EN 10305-1 Seamless Precision Steel Tubes Manufactured?

The manufacturing process of EN10305-1 seamless precision steel tubing begins with high-quality carbon steel billets. These billets are heated and perforated to form hollow steel pipes. Next is cold drawing, which pulls the tube through the mold and mandrel to obtain precise dimensions and smooth surface finish. The cold drawing process enhances the mechanical properties of steel pipes, including their tensile strength and hardness. Not all steel tubing have the same performance, they have different manufacturing processes.

Cold drawing is important for producing pipes with strict tolerances and excellent surface quality. Some seamless pipes may undergo further processing, such as heat treatment, to release internal stress and improve machinability.

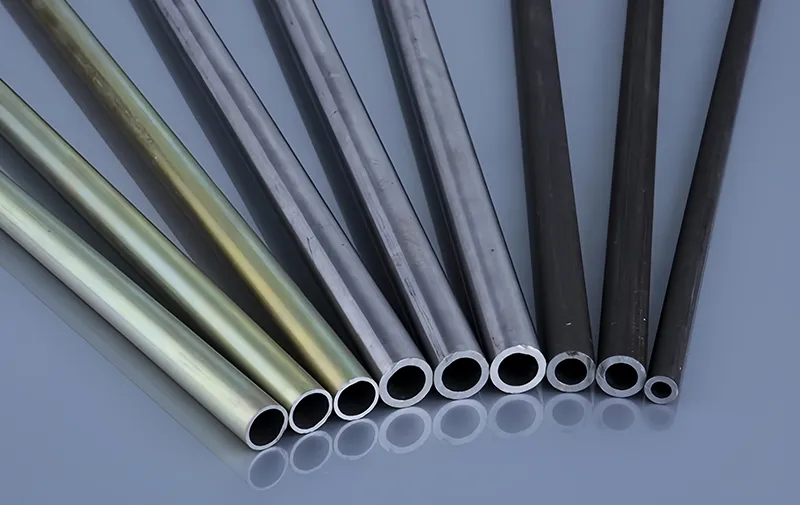

Cold-drawn seamless tubes have excellent dimensional accuracy, straightness, and surface smoothness. Surface treatments such as galvanizing or phosphating can also be used to enhance corrosion resistance. Most seamless steel pipes are cold drawn.

What Are the Different Steel Grades Within EN 10305-1?

The EN 10305 standard includes several steel grades, each tailored to meet specific application requirements. For example: E235, E215, E355, and E255.

E235 is a commonly used steel grade with good weldability, formability, and machinability. It is suitable for general engineering applications that require moderate strength. E215 is another steel grade with similar performance, slightly different chemical composition, while E355 is the best choice when higher strength and durability are crucial. On the other hand, E255 achieves a good balance between strength and formability and is commonly used in hydraulic cylinder tubes assembly.

Why Choose Cold Drawn or Cold Rolled Precision Steel Tubes?

The choice between cold drawn or cold-rolled precision steel pipes depends on specific requirements. Cold drawn tubes are an ideal choice due to their excellent dimensional accuracy, smooth surface finish, and enhanced mechanical properties. The cold drawing process involves pulling the tube through a mold to reduce its diameter and wall thickness, while improving its strength and surface quality. This process is highly suitable for applications that require strict tolerances and high-quality surface treatment.

Cold rolled tubes are produced by rolling steel through a drum at room temperature. This method also improves the strength and surface finish of steel, but may not achieve the same level of precision as cold drawing. Cold rolled seamless pipes are usually used in places where cost is low and precision requirements are not too strict. Cold drawn precision steel tubes are better than cold-rolled steel tubes. They are most commonly used in the production of hydraulic systems.

Cold Drawn Precision Tube:

- Strength enhancement: Cold drawing process can improve the tensile strength and yield strength of steel.

- Surface smoothness improvement: The surface of the cold drawn tube is smoother and more uniform.

- Dimensional accuracy: This method can make the tolerance of pipe dimensions more stringent.

Cold Rolled Precision Tubes:

- High cost-effectiveness: Generally, cold rolling is cheaper than cold drawing.

- High strength: Although cold-rolled pipes may not have the same strength as cold drawn pipes, their mechanical properties are still superior to hot-rolled pipes.

- Widely applicable: Suitable for a wide range of applications that do not require high precision.

Where Are Applications of EN10305 Tubes in Industries?

EN 10305-1 seamless precision steel tubes are mainly used in hydraulic and pneumatic systems. These precision tubes transport fluids under high pressure. In the automotive industry, EN10305 tubing are used for fuel lines, suspension components, and other critical components that require precision and durability. In addition, EN10305 seamless tubes can also be used in mechanical manufacturing, construction, and even medical equipment. For example:

Hydraulic system: Seamless tubing are used for hydraulic cylinders, pumps, and valves due to their high pressure resistance.

Automotive Industry: The automotive industry often uses these precision pipes for fuel injection pipelines, brake pipelines, and power steering components.

Mechanical manufacturing: Precision components used for various types of machinery, including those used in the textile, printing, and packaging industries.

Construction: Steel tubes are used for structural components that require high strength and precision.

Click Here To Learn Seamless Steel Tubes Application!>

How Does EN 10305-1 Compare to DIN2391?

EN10305 and DIN2391 are both standards. EN 10305 is a widely recognized standard for seamless cold drawn precision tubes, while DIN 2391 is a German standard that also covers seamless precision steel tubes and is generally considered equivalent to EN 10305-1 in many aspects. However, the specified steel grade, chemical composition, and mechanical properties may vary slightly.

Both standards strictly control OD (outer diameter) and wall thickness, surface quality, and mechanical properties. In many cases, pipes that comply with EN 10305-1 or DIN 2391 can be used interchangeably. If you need more specific steel grade information, please feel free to contact us at any time.

Click Here Learn DIN2319 Seamless Stee Tubes>

How to Choose the Right EN10305 Tube Supplier?

Choosing a suitable seamless precision steel tubes supplier, the supplier’s industry experience and reputation are important. Looking for suppliers with a good track record of providing precision tubes that comply with international standards such as EN 10305-1. For example,

Global Hydraulic Steel Tube is one of the leading suppliers of EN 10305-1 seamless precision steel tubes and a well-known manufacturer. You can purchase high quality EN 10305-1 steel tubes from our company.

Quality control is another key factor. Ensure that suppliers have a strong quality management system and that their products undergo rigorous testing and inspection. Obtaining ISO 9001 and other related standard certifications can provide additional quality assurance.

Suppliers have the ability to provide customized solutions, such as specific tube sizes, steel grades, or surface treatments, to meet your unique requirements.

Seamless Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.

Conclusion

EN 10305-1 seamless precision steel tubes can influence the success of a project. Whether in hydraulic systems, automotive components or precision machinery, choosing the right material and supplier is crucial.

Contact “Global Hydraulic Steel Tube Company” today for high quality EN10305 precision seamless steel tubes and unmatched customer support. Other Related Product: Galvanized Seamless Steel Tubes>, Phosphated Seamless Steel Tubes>, Honed Tubes>, Hard Chrome Rod>, Tube Assembly>.