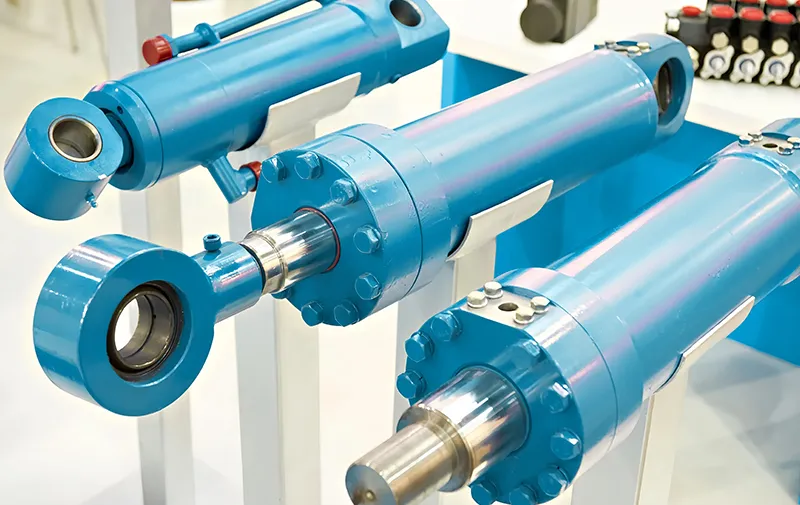

Honed tubes are the materials of the core components of hydraulic cylinders and telescopic cylinders. The quality of the honed tube directly affects the operation of the cylinder. Golbal HydraulicSteelTube focuses on the research and development of high-precision seamless honed tubes. Provide reliable hydraulic solutions for the industrial field.

Our honed tubes are made of high-quality carbon steel or alloy steel. After precision machining, the inner wall surface roughness is controlled within the range of Ra0.2-0.4μm, and the straightness error does not exceed 0.1mm/m. This precision can reduce the running resistance of the piston bar. Improve the working efficiency of the hydraulic cylinder.

What is Honed Tubes?

Honed tube is a precision machined steel tube. It is mainly used in the manufacture of hydraulic cylinders or telescopic cylinder barrels. The inner wall roughness of the tube is controlled to the micron level through a unique honing process. This ensures the accuracy of the inner diameter (ID) size of the bunished tube.

The honing process can form a uniform oil storage structure and ensure the smoothness of the piston movement. It’s can reduce the friction between the piston rod and the inner wall components of cylinder. Increase 14-21% mechanical efficiency of hydraulic cylinder

Why Honed Tubing is Crucial for Hydraulic Cylinders?

Honing process can control the internal roughness of hydraulic honed tube to Ra=0.2-0.4μm. Tolerance standard of the inner diameter of the tube can comply with ISO H7, ISO H8, ISO H9. High precision ensures stable operation between the piston rod and the cylinder. This improves the working efficiency of the hydraulic cylinder. It also enhances the fatigue resistance of the cylinder and reduces the risk of leakage.

Manufacturing Process of Pre Honed Steel Tubing

Honed tubeing are produced with an innovative production process system and strict standards. Ensure that they meet strict quality standards. Unlike welded tubes, seamless steel tubes have advantages in mechanical properties and reliability due to their seamless structure.

Three key links:

Cold Drawing Process: Through multiple passes of diameter reduction and stretching, the outer diameter size (tolerance ±0.05mm) and wall thickness uniformity (deviation ≤5%) are accurately controlled under the support of the mandrel

Honing Process: Use high-precision CNC honing equipment, combined with diamond grinding tools, to control the inner surface roughness within the range of Ra0.2-0.4μm.

Precision Measurement: 100% full inspection of the inner diameter size of the tube to ensure that they meet specific requirements.

The seamless structure of honed bunished tube gives it excellent pressure-bearing performance. It is suitable for high-pressure hydraulic systems above 35MPa. For example: heavy-duty fields such as engineering machinery and ship hydraulics.

Why Choose Seamless Honed Tubes for Hydraulic Applications?

Based on the technical advantages of seamless honing tubes, it is widely used in the field of hydraulic system design and manufacturing.

Structural integrity: The seamless structure adopts the overall cold drawing forming process to avoid the heat affected zone and weld stress concentration problems existing in welded tubes.

Accurate size: Through the honing process, the inner diameter (ID) tolerance can be controlled at ±0.01mm and the outer diameter (OD) tolerance can be controlled at ±0.05mm. The internal leakage rate is reduced.

Surface roughness: Bunished honing tubes reduce the friction coefficient of the inner wall and increase the service life of the piston rod moving parts.

Honed Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.

Understanding ID and OD Measurements in Cylinder Tubes

Accurate ID and OD measurements are critical to the manufacture of cylinder tubes. OD determines the integrity of the tube, ID determines the internal dimensions after honing:

ID dimension affects the quality of the piston and cylinder fit. Controlling the ID tolerance within ±0.01mm reduces the piston rod movement resistance by 30-40%, and the internal leakage is <0.1mL/min.

OD accuracy affects the assembly quality of the cylinder and the end cover. Controlling the OD tolerance within ±0.05mm makes the assembly stress distribution uniform.

We provide a variety of tube diameters to meet various specifications. Make it compatible with different hydraulic cylinder designs.

The Role of Chrome Plated Rods in Hydraulic Cylinders

chrome plated piston rod is a key moving part in the hydraulic cylinder. It’s performance affects the reliability of the entire system.

Chrome plating process: Through the hard chrome plating process, a chrome layer with a thickness of 0.03-0.05mm is formed on the surface of the bar. The hardness of the chrome layer reaches HV800-1000. Thereby improving corrosion resistance and resisting chemical erosion of hydraulic oil.

Friction optimization: Precision grinding and superfinishing process, control surface roughness Ra=0.1-0.2μm. Reduce wear rate.

The composite process of induction quenching + chrome plating is adopted. The surface hardness of coating is: HRC65-75, fatigue strength is: ≥500MPa

How Honing Ensures Precision

In the manufacturing process of hydraulic cylinders, honing technology is the core technology for achieving precision machining.

Abrasive honing: CNC honing equipment is used with diamond grinding tools to control the inner surface roughness through multi-stage honing process. Thereby eliminating microscopic defects and forming a 120° cross-net structure.

Inner diameter size control: A high-precision online measurement system is used to monitor the inner diameter size in real time.

Quality assurance: Each tubes is 100% endoscopically inspected, mechanical properties tested, dimensionally inspected, and pressure tested. Ensure that the product qualification rate reaches more than 99.9%.

Standards and Their Relevance to Steel Tubing

Our production system follows international standards such as ASTM A519, DIN 2391 EN 10305. Ensure product reliability:

Material specifications: We use high-grade st52, E355, SAE 1026 and other steels that have been honed to meet industry requirements.

Mechanical performance guarantee: Ensure product tensile strength: 850-1000MPa, yield strength: ≥700MPa, elongation: ≥12%.

Quality verification system: Each batch of products is strictly tested to ensure compliance with international standards and can be used in various industries.

Ensure that the product is suitable for key areas such as engineering machinery and ship hydraulics, providing reliable performance guarantee for hydraulic systems.

Industry Applications of Honed Tubes

In the manufacturing process of hydraulic cylinders. Honing technology is the core technology for achieving precision machining.

Hydraulic Industry: Essential for manufacturing hydraulic cylinders and systems.

Automotive Sector: Used for shock absorbers, steering systems, automatic transmission parts..

Industrial Manufacturing: presses, injection molding machines and CNC machine tools.

Pneumatic Systems: Applicable where air pressure is used for motion control.

The use of our precision honed tubes spans across several industries, highlighting their importance as important materials in modern engineering.

Choosing the Right Honed Tube Manufacturer and Supplier

Choosing a reputable honed tube manufacturer can impact the quality of your product:

Strength Guarantee: 20 years of experience in precision steel tube manufacturing, 10 core process patents, 5 fully automatic CNC production lines.

Quality Assurance: ISO9001 quality management system certification, 100% dimensional inspection.

Customer Support: Professional technical team, 24-hour rapid response, full life cycle technical support.

Competitive Pricing: Large-scale production reduces manufacturing costs, and the advantages of centralized procurement of raw materials.

Contact Us>. By partnering with us, you gain access to superior products and dedicated service.

Frequently Asked Questions About Hydraulic Cylinder Tubing

Q1: What sizes are available for honed tubes?

A1: We offer a range of sizes, including various OD and ID measurements, and wall thicknesses, accommodating metric and imperial dimensions. ID: 30.0~700.0 mm, OD: 40.0~1000.0 mm

Q2: Are custom lengths available?

A2: Yes, we provide customized tube lengths to meet your specific requirements.

Q3: Do you offer samples?

A3: Absolutely! We provide samples to verify quality before placing a bulk order.

How to Order?

Ready to enhance your hydraulic systems with our top-tier honed tubes>?

Contact Us: Reach out for a quote or to discuss your requirements.

Free Samples: Request samples to assess quality firsthand.

Bulk Orders: Benefit from discounts on large orders.

Click here to fill out our inquiry form and get started today!

Honed Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.

Conclusion

The quality of precision honed tubes directly affects the optimal performance of hydraulic cylinders. As an experienced manufacturer and supplier, we are committed to providing products that meet the highest standards of precision and durability. Our comprehensive product range, competitive pricing and excellent customer service make us the ideal partner for all your honed tube needs.

Related Product: Seamless Precision Hydraulic Steel Tubes>, Hard Chrome Rod>, Tube Assembly>.