In hydraulic and pneumatic systems, selecting suitable hydraulic tuibing can ensure smooth fluid transmission. Seamless hydraulic tubes are similar to the blood vessels of the human body, maintain normal internal operations.

We need to consider the working pressure, corrosiveness, temperature, and specific application scenarios of the fluid. By comprehensively analyzing these factors, we can make wise choices to avoid system abnormalities caused by hydraulic pipe quality issues.

What is Hydraulic Tubing?

In the field of fluid transmission, hydraulic tubing are transmission channels in pneumatic and hydraulic systems. These precision tubes are usually made of high-quality steel. It is dedicated to transmitting pressure and hydraulic oil. It mainly drives the operation of mechanical equipment by controlling the hydraulic system.

Compared with flexible hoses, hydraulic steel tube structures can effectively carry working pressures above 70MPa. It has higher durability and resistance to media corrosion. High precision pipes can ensure stable operation in high-pressure environments.

- Hydraulic tubing is a closed loop system where the hydraulic fluid is kept.

- The hydraulic tube transports the hydraulic fluid to the cylinders.

- This tube is made of steel, which is a steel tube.

- The wall thickness is important.

Key Factors to Consider When Selecting Hydraulic Tubing

There are many important factors to consider when selecting hydraulic pipes. From material compatibility, pressure loads to temperature. The dimensional accuracy and wall thickness of the hydraulic pipe ensure the normal operation of the system. These factors ensure the durability and stability of steel hydraulic pipes.

Pressure loads: Every hydraulic and pneumatic system needs to operate under specific pressure conditions. The peak pressure value and safety factor of the hydraulic system must be accurately matched

- Pressure Rating: Every hydraulic and pneumatic system needs to operate under specific pressure conditions. The tube must be able to withstand the maximum working pressure.

- Tube Size: The diameter and wall thickness of hydraulic steel tubing must meet the requirements. The inner diameter size affects the flow rate and pressure loss. Choosing the right pipe size can minimize energy consumption.

- Temperature: Extreme temperatures can degrade the hydraulic tube.

- Size: Diameter and wall thickness matter.

- Material: seamless carbon steel, alloy steel, stainless steel.

Understanding these key factors, you can make an informed decision when selecting your hydraulic tube. The correct tube will make sure the hydraulic system is functional.

- Pressure rating.

- Temperature ratings.

- Size and diameter.

- Material type.

- Application.

How Does Hydraulic Tubing Size Affect Performance?

Improper dimensional accuracy control may lead to reduced system efficiency. This can cause pipeline failure. In fluid power systems, hydraulic pipes are metal carriers, and the slightest difference in their inner diameter and wall thickness determines the stability of the entire transmission system.

- Diameter: The diameter is the size of the tube.

- Wall thickness: The wall thickness is the steel thickness of the tube.

- Flow rate: The diameter affects the flow rate of the hydraulic.

- Higher pressure: You will need a thicker tube.

Therefore, when selecting hydraulic pipes, factors such as the operating pressure of the application equipment system, flow requirements and corrosion characteristics should be comprehensively considered. If necessary, pressure testing and flow verification can be carried out.

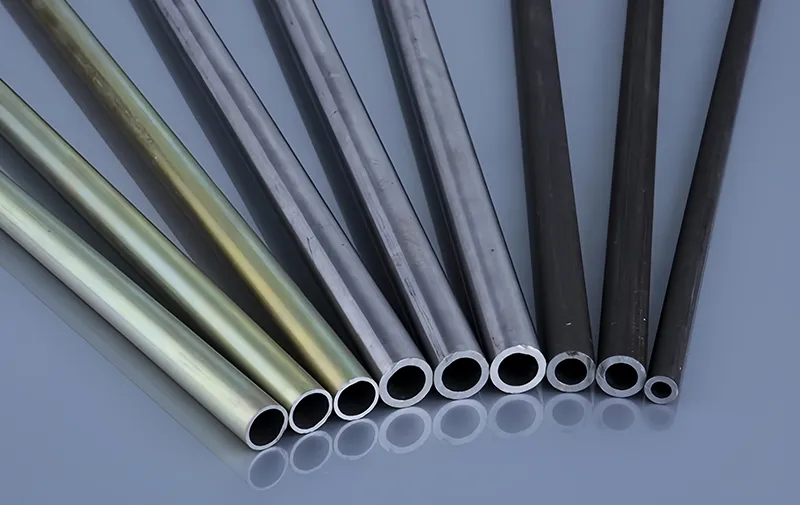

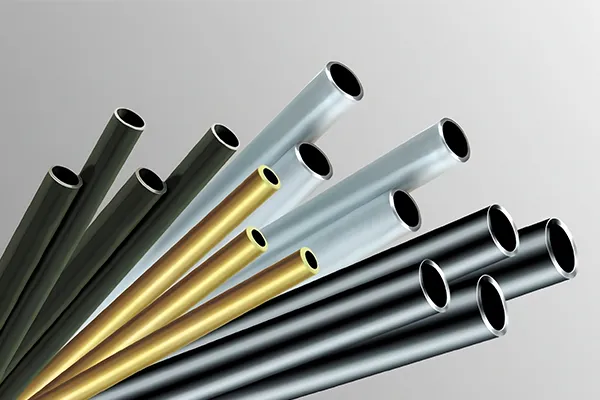

Types of Hydraulic Tubing Materials

Seamless steel tubes have excellent mechanical properties and pressure resistance. Stainless steel has good corrosion resistance. In practical applications, materials are mainly divided into the following categories:

- High-quality Carbon Steel (such as 20#, 45# steel): Applicable to conventional industrial environments. Good machining performance. Excellent cost performance. Working pressure range: 16-40MPa

- Alloy Steel (such as 27SiMn, 30CrMo) : Applicable to high pressure and heavy load conditions. Tensile strength can reach more than 900MPa. Excellent fatigue resistance. Working pressure range: 40-70MPa.

- Austenitic Stainless Steel : Stainless steel materials have strong corrosion resistance. Especially for chloride ions. This type of material is widely used in industries with high hygiene requirements such as food and medicine.

- Material Selection Suggestions: 20# seamless steel pipe is preferred for conventional industrial environment. 27SiMn alloy steel pipe is recommended for high-pressure system. 316L stainless steel pipe is recommended for corrosive environment such as marine engineering. 304 and above stainless steel pipe is required for food and medicine industry

Material selection needs to comprehensively consider working pressure, medium characteristics, environmental conditions and other factors. If necessary, material performance test and life evaluation can be carried out to ensure the reliability and economy of the system.

Seamless vs. Welded Hydraulic Tubing

In hydraulic systems, tubes selection needs to be based on equipment and performance requirements. Seamless hydraulic tubing are integrally formed structures without welds. Has high pressure bearing capacity and reliability. Suitable for high-pressure and high-intensity working environments. But the production cost is also correspondingly high.

Welded hydraulic tubes are made using roll welding technology, which may result in poorer pressure performance. But the manufacturing cost will be lower.

- Seamless tubing: High pressure and is without welds.

- Welded tubing: Cost-effective.

How to Ensure Hydraulic Tubing Compatibility with Hydraulic Fluids

Hydraulic fluids can affect the hydraulic tube. It’s essential to confirm the hydraulic fluid and hydraulic tube are compatible. Some fluids may degrade or corrode certain tube materials. For instance, some fluids might cause corrosion resistance issues with certain steel tubes.

Hydraulic fluids can affect hydraulic tubes. It is critical to ensure that the hydraulic fluid and hydraulic tubes are compatible. Certain fluids can have degrading or corrosive properties. For example, certain fluids can cause corrosion issues with steel tubes.

Hydraulic fluids used in hydraulic systems vary. The wrong type of hydraulic fluid can cause tube failure. Be sure to check compatibility and ensure long life for your hydraulic tubes.

Installation and Maintenance of Hydraulic Tubing

Proper installation and maintenance are critical to ensure the long life of a hydraulic tube. Poor installation can create leaks. Proper installation will save you money in the long run. Inspecting hydraulic tubing is essential.

- Installation is critical.

- Inspect your tubing regularly.

- Look for leaks.

Routine inspections can catch problems. Regular inspection can prevent costly hydraulic system failures. If you notice a leak, repair or replace the hydraulic tube immediately.

Selecting and Using Hydraulic Tube Connectors and Fittings

The fitting selection is critical for a hydraulic tube system. Connectors and fittings ensure a leak-free and secure connection. Choose the right fitting.

- Connectors are used to connect the tube.

- Select the right fitting.

- Make sure they are compatible.

Selecting the proper fittings ensures the reliability of your hydraulic system. It is important to select the right fitting for the hydraulic system.

Industry Standards and Regulations for Hydraulic Tubing

Industry standards and regulations provide a crucial framework for hydraulic tubing. Compliance is key to ensure safety and performance. These standards help ensure the hydraulic system performs.

- SAE standards.

- Regulations matter.

Understanding and following these guidelines can also ensure that your hydraulic system is operating safely. We adhere to all applicable industry standards.

Conclusion

Choosing the right hydraulic tube is crucial to the smooth operation of pneumatic and hydraulic systems. The application of the tube is very important, you must choose the right tube for your hydraulic system to ensure the reliability of the hydraulic system. Consider the size of the tube, what material to choose for the hydraulic tube, and how the hydraulic system will be used.

Global Hydralic Steel Tube is a Leading China Manufacturer. They have seamless steel hydraulic tubing for hydraulic systems, honed tube for hydraulic cylinder. Contact Global.

Refer To: Industrial Tube