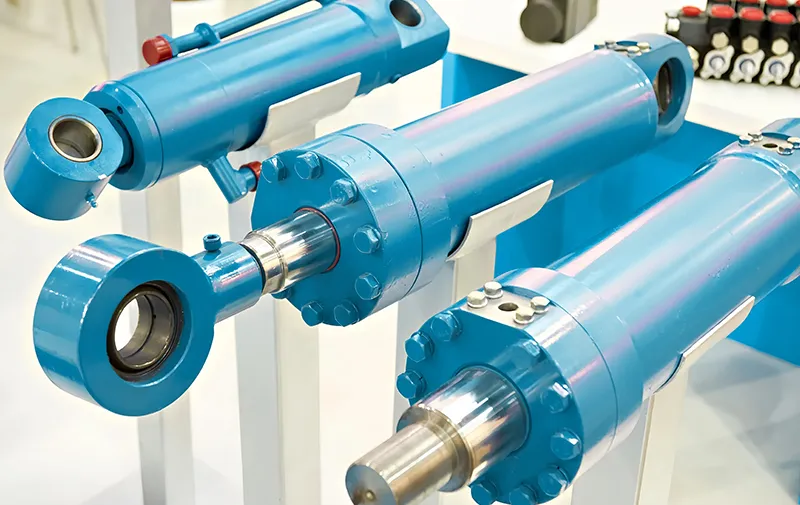

Hydraulic cylinders are the driving force for many machinery and industrial equipment, making them run more smoothly. Next, we will mainly discuss hydraulic cylinders. Mainly introduce important components such as rods, pistons, chrome plating, etc.

What Are Hydraulic Cylinders?

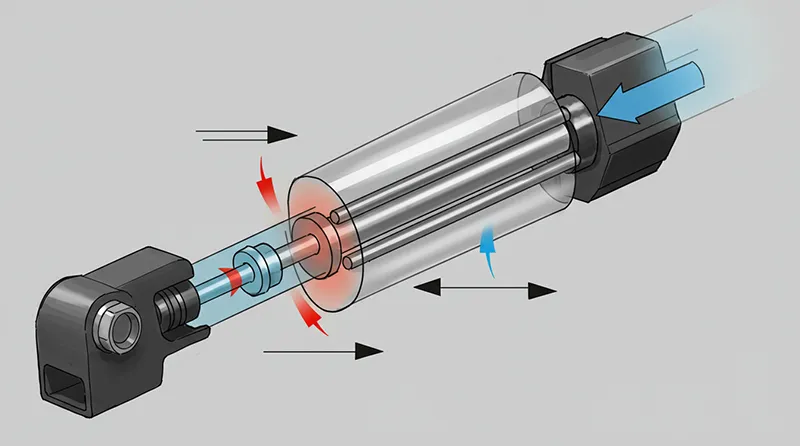

Hydraulic cylinder is a mechanical actuator in hydraulic transmission system. It’s mainly converting hydraulic energy into mechanical energy. It provide one-way force. Hydraulic cylinders are widely used in fields such as construction machinery, agricultural machinery, engineering vehicles, and industrial automation.

Initially, hydraulic cylinders were used to perform heavy lifting projects. Now, they can achieve precise movement in a variety of applications from machinery to vehicle parts. Their versatility is largely due to their construction and adaptability.

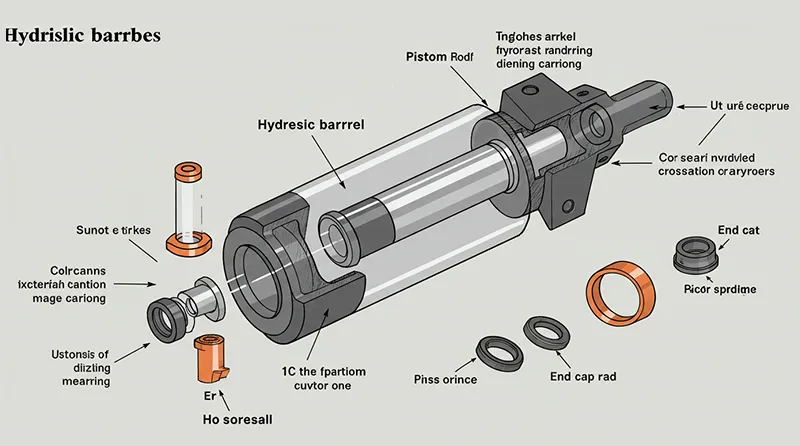

Key Components of Hydraulic Cylinders

The main components of hydraulic cylinders are: cylinder barrel, piston rod, piston, end cover, seal, etc.

Cylinder barrel

The main spare parts of hydraulic cylinders are made of honing tubes. Used to carry hydraulic oil and provide a motion channel for the piston rod.

Piston

Located inside the cylinder, it divides the inner cavity of the cylinder into two independent chambers, and the movement of the piston is driven by hydraulic pressure, producing linear or upward movement.

Chrome Piston rod

Connected to the end of the piston, used for outputting mechanical motion and connected to external loads.

End cover assembly

Integrated guide sleeve and sealing system, flange or threaded connection. Dustproof seal to prevent the entry of contaminants. Prevent hydraulic oil leakage

Seal

is installed between the piston and the cylinder barrel and at the end cover to ensures that there is no liquid leakage.

Why Choose Hard Chrome Plated Rods?

Choosing a chrome plated rod significantly improves the cylinder’s durability. Chrome’s unique properties provide a layer that resists corrosion, damage, and abrasion.

“Chrome plated rods offer longevity and ensure consistent performance,” states an industry expert.

How Do Hydraulic Cylinders Work?

Hydraulic cylinders can convert fluid power into linear mechanical force and motion. By applying hydraulic pressure, these forces can precisely move heavy objects.

This precise force-displacement control feature enables piston rods to be used in construction machinery (excavators, cranes), industrial equipment (such as rolling mills, die-casting machines) and other equipment.

How Hydraulic Cylinder Repair?

As the hydraulic cylinder runs for a long time, its performance will deteriorate. By implementing a preventive maintenance plan, the failure rate of hydraulic cylinders can be reduced by more than 60%.

Leak detection: Monitor the pressure-time curve. When the system pressure drops by more than 15%, there may be a leakage problem.

Wear condition: Use an endoscope to check the wear of the piston seal and rod seal.

Seal replacement: Use special installation tools to replace the sealing system components regularly.

Precision repair: For slightly deformed rods, a hydraulic straightening machine can be used for cold correction.

Selecting the Right Cylinder Rod

Choosing a hydraulic cylinder involves considering the load, strength, and specific requirements of your application. The size, length, and diameter must align with your machinery’s operations.

Key Considerations

- Material strength: Opt for induction hardened rods for durability.

- Load capacity: Match the psi requirements to your equipment.

What is Tie Rod Hydraulic Cylinder?

The tie rod hydraulic cylinder is renowned for its engineered design and reliability in diverse applications. They are easily maintained due to their detachable components.

Advantages

- Compact design: Suitable for smaller or more confined spaces.

- Low maintenance: The tie rods can be easily accessed for repair or replacement.

How to Extend the Lifespan of Hydraulic Cylinders

Regular inspection and maintenance of hydraulic cylinders are required to extend their service life. Starting from implementing maintenance plans, monitoring operational efficiency, and using high-quality hydraulic products.

The Role of Engineering

Professional engineers use the latest technology to improve the accuracy and service life of hydraulic cylinders. Their expertise ensures that each cylinder meets its specifications and load requirements.

Conclusion

Get a comprehensive understanding of hydraulic cylinders. Regularly maintain hydraulic cylinders, use plated rods to increase durability, etc. Ensure that your current machinery and equipment operates efficiently.

To learn more about seamless steel tubes, please contact us today. Please visit our products: seamless precision steel hydraulic tube>, honing tube>, chrome piston rods>.

Honed Steel Tubes

Meet The Production Needs of Manufacturers. Increase Your Net Profit.