Прецизионные бесшовные стальные гидравлические трубки на заказ

Спецификация сборки прецизионных стальных труб

Введение в производство:

Сырье: Прецизионные бесшовные стальные трубы из углеродистой стали

Процесс: Холодная вытяжка или холодная прокатка

Стандарт: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391/C), GB/T3639, ASTM A179

Материал: ST37.4,ST35,ST45,ST52,E235,E355

Испытание соленым аэрозолем: ≥ 120 часов

Размер: Наружный диаметр (OD): 4.0mm~80.0mm, Толщина стенки (WT): 0.5мм~8.0мм

Наружный диаметр (OD) Стандартный размер: 4 мм, 6 мм, 8 мм, 10 мм, 12 мм, 14 мм, 15 мм, 16 мм, 18 мм, 20 мм, 22 мм, 25 мм, 28 мм, 30 мм, 32 мм, 35 мм, 38 мм, 40 мм, 42 мм, 45 мм, 50 мм, 55 мм, 60 мм, 70 мм, 80 мм, 100 мм

Обработка поверхности: Гальванизация, фосфатирование, травление или другие процессы.

Бесшовные оцинкованные стальные трубы: Стандартная толщина цинкового покрытия составляет от 8 до 12 мкм

Фосфатирование стальных труб: Внешнее фосфатирующее покрытие

Образец: Мы можем предоставить образцы бесшовных стальных труб из углеродистой стали для испытаний.

Химический состав бесшовных стальных труб в сборе:

Механические свойства гидравлических трубок в сборе:

Распространенные типы соединений:

Стыковые соединения: Трубы выравниваются по торцам и свариваются вместе, обычно с помощью таких методов, как электродуговая сварка (EAW). Стыковые соединения предпочтительны из-за их высокой прочности на разрыв.

Нахлесточные соединения: Трубки частично перекрываются и свариваются, обеспечивая некоторую гибкость и подвижность между соединенными трубками.

Фланцевые соединения: Трубки соединяются с помощью фланцев и болтов, обеспечивая надежное и разъемное соединение.

Применение прецизионных бесшовных труб в сборе

Благодаря передовым технологиям бесшовные прецизионные трубы из углеродистой стали разработаны для удовлетворения строгих требований широкого спектра отраслей промышленности. Превосходная прочность, точность и долговечность делают их выбором, которому можно доверять:

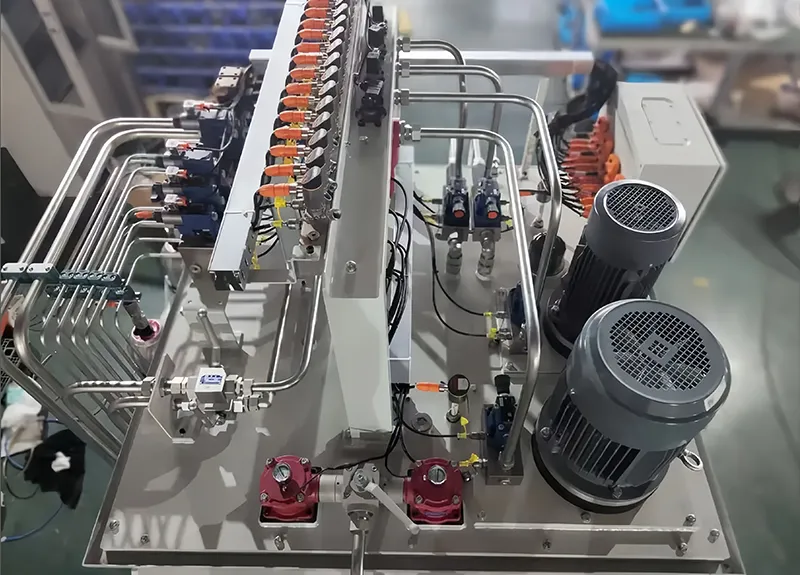

Гидравлические или пневматические системы: В основном используются в трубопроводах и стрелах строительной техники, сельскохозяйственных машин и промышленного оборудования.

Автомобильная промышленность: В качестве ключевого компонента в системах подвески, топливопроводах и других деталях точного машиностроения.

Промышленное оборудование: Обеспечивают мощные и точные решения для подачи жидкости и поддержки конструкций.

Аэрокосмическая и оборонная промышленность: Соответствие строгим стандартам производительности и безопасности в условиях повышенного риска.

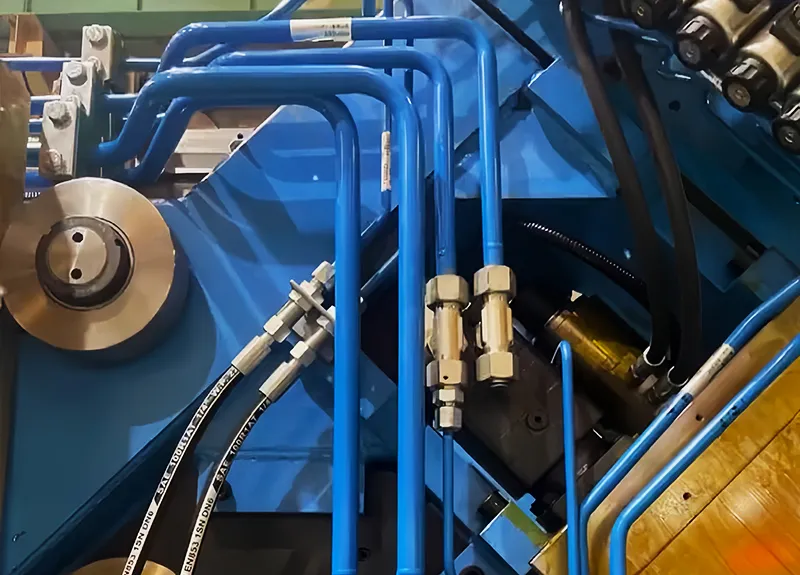

Машинная стрела

Линии гидравлической системы

Гидравлическая или пневматическая система

Завод

Наша фабрика имеет более чем пятнадцатилетний опыт экспорта, обладает передовым производственным оборудованием и сотрудничает с клиентами в более чем сорока странах.

Мастерская по производству бесшовных стальных труб

Завод бесшовных прецизионных стальных труб

Бесшовные стальные гидравлические трубы завод

Свяжитесь с нашими экспертами напрямую!

Также вы можете связаться с нами напрямую по адресу: [email protected]".