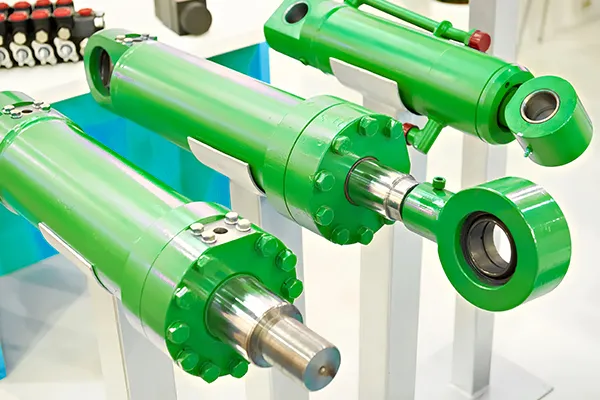

Pre Honed Tube - Hydraulic Cylinder Tube Supplier

As a leading manufacturer and supplier of honed tube in China. Our honed tubing are widely used in hydraulic cylinders, pneumatic systems, semiconductor Industry amd more.

Honed Tube Manufacture

Our seamless honed tube are made of alloy steel and carbon steel rather than stainless steel. Hydraulic cylinder tube strictly comply with international standards, such as DIN2391, EN10305, ASTM A519, GB/T3639-2000.

The inner wall treatment process of pre honed steel tubing includes cold rolling, honing and skiving. Honed tubing are made of high-strength materials, including: C20, CK45, Q355B, Q355D, E355 (ST52), SAE1026, SAE4130 4140, STKM 13C .

honed tubes for hydraulic cylinders are used in a variety of industries. Including: engineering machinery, agricultural machinery, material handling equipment, automobiles and industrial equipment. Directly used in the pipes of hydraulic cylinders and telescopic cylinders.

Features:

- 100% Quality Control

- High precision

- Good performance

- Inside Diameter (ID): 30.0~700.0 mm

- Outer Diameter (OD): 40.0~1000.0 mm

- Length: 3.0~9.0m. Can be customized according to customer needs

Hydraulic Cylinder Tube Details

Inner Wall Treatment Process

The inner surface treatment of high quality honed tubes is mainly cold-drawn, honing, and skiving. For hydraulic cylinder tube (HP type), the inner surface of tubing is peeled and rolled. For machined tubes (HPZ type), the inner surface of tube is machined, honed, or peeled and rolled.

Pre Honed Tube - Finished

Honed Coss tube is mainly made into cylinder barrels of hydraulic cylinders, telescopic cylinders, cylinder liners, and machined tubing.

Precision Hydraulic Steel Tubes & Chrome Rod

Our factory can also provide seamless precision steel tubes and hard chrome plated rods. Widely used in hydraulic industry and pneumatic system. Contact us today for more details.

Seamless Steel Honed Tube Application

Our factory honed steel tubes are widely used in engineering machinery (such as excavators, cranes), agricultural machinery, logistics handling equipment, construction equipment, industrial equipment, etc. These hydraulic cylinder tubing are made of high-strength steel and precise technology. They have high pressure resistance and corrosion resistance. The inner wall of tube is processed more precisely, thus reducing the friction coefficient. Whether it is a high-pressure hydraulic system or a medium and low-pressure transmission system, our honed pipes can meet the solutions of various industries.

Telescopic Cylinder

Used to be processed into telescopic cylinders for various types of engineering machinery and agricultural machinery.

Hydraulic Cylinder

Processed into hydraulic cylinder barrels for construction machinery, agricultural machinery, and industrial equipment.

Hydraulic System

Honed tubes and piston rods are processed into hydraulic cylinders. Tank components with seamless precision steel tubes are used in the hydraulic system of the equipment.

Seamless Honed Tubing Quality Control

As one of the top 3 honed tube manufacturer in the world. Our factory has a dedicated quality inspection team that can provide seamless hydraulic cylinder tube product quality inspection services, such as: inner wall roughness, inner wall cleanliness, whether the inner wall is rusty, etc. . The outer diameter of tube, wall thickness tolerance, scratches, warping, bumps, etc.

Endoscopic Inspection

Honed Pipe inner wall dimension inspection.

Appearance Inspection

Check the appearance to see if honing tubes meets customer requirements

Point Alignment

Our factory has specialized equipment for straightening and honing pipes

FAQ For Honed Pipes

What is Honed Cylinder Tube?

Honed cylinder tube is a raw material for hydraulic cylinders or telescopic cylinders, usually made of seamless pipes. It is processed by precision cold rolling, honing to ensure smooth inner wall and reduce roughness.

What’s the Difference Between Seamless Honing Tube and Ordinary Steel Tube?

Seamless honing tube uses high-strength steel, has higher inner wall precision, can effectively improve drug resistance and wear resistance. Suitable for hydraulic and pneumatic systems. Ordinary steel pipes do not have these precision requirements and usually cannot meet the high pressure and high efficiency requirements of hydraulic cylinders.

What Materials are Honed Tubes Made From?

- Our honed tubes are made from high-quality carbon steel, alloy steel to ensure durability and performance.

Carbon steel has 20#, 40# and SAE 1026 steel and more.

Alloy steels include ST52, SAE 1020 and more.

What’s the Surface Roughness of Hydraulic Cylinder Tubes?

According to the different inner wall treatment processes of pipes, the roughness control is different. Skiving: 0.2µm, Honed: 0.4-0.8µm, Cold-drawn: 0.8-1.6µm.

What’s the Dimensional Tolerance of Honed Tubes?

The tolerance of the honing process is H8-H9, and the tolerance of the scraping process is H8.

What Industry are Honed Steel Tubing Suitable For?

Engineering machinery (such as excavators, cranes, mining machines), agricultural machinery (such as tractors, harvesters), material handling equipment, automotive industry, automation equipment and hydraulic transmission systems

Is Your Company a Manufacturer?

- Yes, we are a factory. We have 10 years of experience in hydraulic cylinder tubes export. We have rich experience in export trade.

How to Get Quotes for Seamless Steel Honed Tube?

You can send us your requirements. Provide product specifications, quantity, delivery location, process and other information, and we will provide the best quotation plan based on your needs.

What Quality Assurance is Provided?

All hydraulic cylinder tubes pass strict quality inspections, including dimensional measurement, surface quality inspection and mechanical performance testing, to ensure compliance with international standards. We also provide comprehensive after-sales service and technical support.

How to Transport the Hoed Tubing for Cylinder Tube?

Our factory provide a variety of transportation methods, including sea, air and land transportation. Choose the most suitable logistics method according to the order quantity, customer location and delivery time requirements.