Cold Drawn Precision Seamless Steel Pipe Assemblies Factory

Precision Seamless Steel Pipe Assemblies Specification

Production Introduction:

Raw Material: Carbon Steel Precision Seamless Steel Tubes

Process: Cold Drawn or Cold Rolled

Standard: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391/C), GB/T3639, ASTM A179

Material: ST37.4,ST35,ST45,ST52,E235,E355

Salty spray test: ≥ 120hours

Size: Outside Diameter (OD): 4.0mm~80.0mm, Wall Thickness (WT): 0.5mm~8.0mm

Outside Diameter (OD) Standard Size: 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 15mm, 16mm, 18mm, 20mm, 22mm, 25mm, 28mm, 30mm, 32mm, 35mm, 38mm, 40mm, 42mm,45mm, 50mm, 55mm, 60mm, 70mm, 80mm, 100mm

Surface Treatment: Galvanized, phosphated, pickling or other processes.

Seamless Galvanized Steel Tubes: Standard zinc coating thickness is 8 to 12μm

Phosphating steel tubes: External Phosphating Coating

Sample: We can provide carbon seamless steel tubes samples for trial.

Chemical Composition of Seamless Steel Pipe Assembly:

| Steel Grade | Chemical Composition% | ||||

| C | Si | Mn | P | S | |

| ST37.4/E235 | 0.07~0.13 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST35 | 0.07~0.13 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST45 | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST52/E355 | 0.13~0.19 | 0.20~0.60 | 1.20~1.60 | ≤0.030 | ≤0.030 |

Mechanical Property of Hydraulic Tubing Assembly:

| Steel Grade | Yield strength | Tensile Strength | Elongation |

| ReH | Rm | A | |

| min. | min. | min. | |

| MPa | MPa | % | |

| ST37.4/E235 | ≥235 | 340 to 480 | ≥25 |

| ST35 | ≥235 | 340 to 480 | ≥25 |

| ST45 | ≥255 | 410 to 520 | ≥25 |

| ST52/E355 | ≥355 | 490 to 630 | ≥22 |

Common Types of Joints:

Butt Joints: Tubes are aligned end-to-end and welded together, typically using methods like Electric Arc Welding (EAW). Butt joints are favored for their high tensile strength.

Lap Joints: Tubes overlap partially and are welded, allowing for some flexibility and movement between the connected tubes.

Flange Joints: Tubes are connected using flanges and bolts, providing a secure and detachable connection suitable.

Application of Seamless Steel Pipe Assembly

With advanced technology, seamless precision carbon steel tubes are designed to meet the stringent requirements of a wide range of industries. Superior strength, precision and durability make them a choice you can trust:

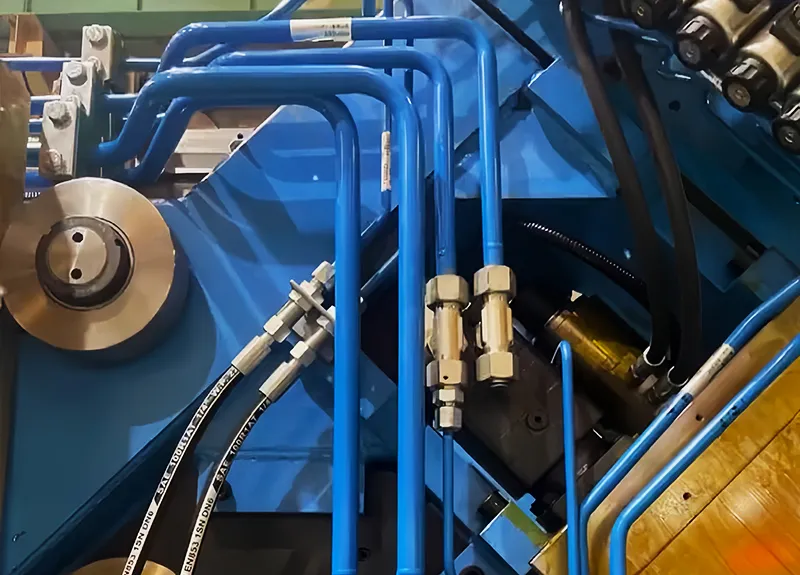

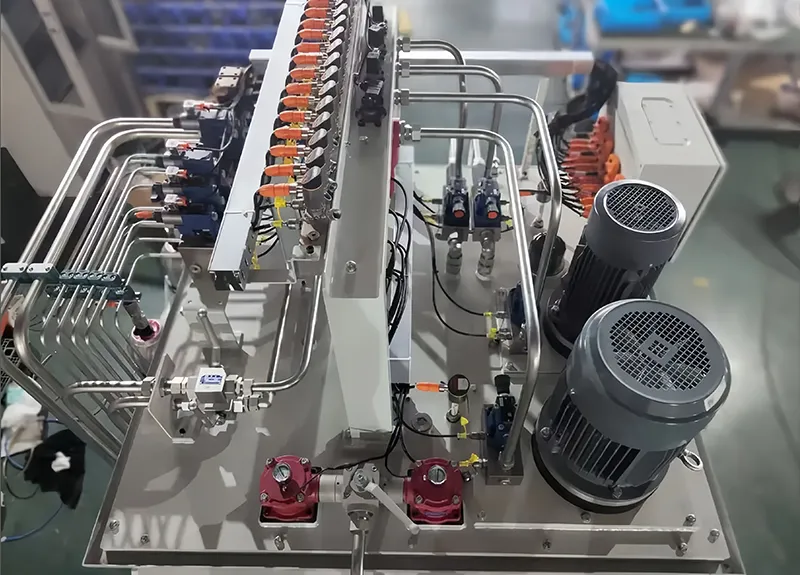

Hydraulic or pneumatic systems: Mainly used in pipelines and booms of construction machinery, agricultural machinery, and industrial equipment.

Automotive industry: As a key component in suspension systems, fuel lines and other precision engineering parts.

Industrial machinery: Provide powerful and precise solutions for fluid delivery and structural support.

Aerospace and defense: Meet stringent performance and safety standards in high-risk environments.

Machinery Boom

Hydraulic System Lines

Hydraulic or Pneumatic System

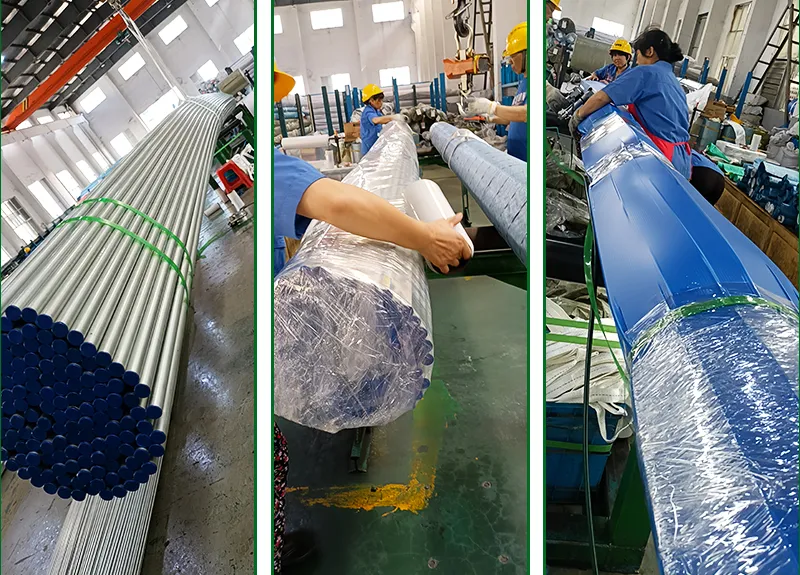

Package & Shipping

All EN1305-1, EN1305-4, DIN2391 cold drawn seamless precision steel pipes are carefully packed to provide maximum anti-collision protection to ensure their intact transportation.

The packaged seamless carbon steel precision hydraulic tubes are packed in wooden boxes or containers. It depends on the quantity of goods.

Packaging for Seamless Hydraulic Tubes

Wooden Box Package