China Cold Drawn Seamless Hydraulic Tube Manufacturer

Cold Drawn Seamless Hydraulic Steel Tubes Specification

Production Introduction:

Shape: Round

Standard: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391/C), GB/T3639, ASTM A179

Material: ST37.4, ST35, ST45, ST52, E235, E355

Salty spray test: ≥ 120hours

Size: Outside Diameter (OD): 4.0mm~80.0mm, Wall Thickness (WT): 0.5mm~8.0mm

Outside Diameter (OD) Standard Size: 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 15mm, 16mm, 18mm, 20mm, 22mm, 25mm, 28mm, 30mm, 32mm, 35mm, 38mm, 40mm, 42mm,45mm, 50mm, 55mm, 60mm, 70mm, 80mm, 100mm

Length: Standard DIN EN Phosphated seamless steel tube length is 6 meters or 5.8 meters. Other hydraulic tubes length dimensions also range from 2 to 12 meters. Also can Customizable length according to customer requirements.

Surface Treatment: Galvanizing, phosphating, pickling or other processes.

Seamless Galvanized Steel Tubes: Standard zinc coating thickness is 8 to 12μm

Phosphating steel tubes: External Phosphating Coating

Sample: We can provide carbon seamless steel tubes samples for trial.

Chemical Composition of Seamless Precision Steel Tubes:

| Steel Grade | Chemical Composition% | ||||

| C | Si | Mn | P | S | |

| ST37.4/E235 | 0.07~0.13 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST35 | 0.07~0.13 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST45 | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 |

| ST52/E355 | 0.13~0.19 | 0.20~0.60 | 1.20~1.60 | ≤0.030 | ≤0.030 |

Tolerance of Seamless Steel Pipes:

| OD/mm | Tolerance/mm | ID/mm Tolerance/mm | Straightness/mm |

|---|---|---|---|

| 4~30 | ±0.08 | ±0.08~±0.15 | 0.1/1000 |

| 30~38 | ±0.15 | ±0.15~±0.20 | |

| 38~50 | ±0.20 | ±0.20~±0.25 | |

| 50~80 | ±0.25~±0.35 | ±0.25~±0.35 |

Mechanical Property of Carbon Seamless Steel Tubes:

| Steel Grade | Yield strength | Tensile Strength | Elongation |

| ReH | Rm | A | |

| min. | min. | min. | |

| MPa | MPa | % | |

| ST37.4/E235 | ≥235 | 340 to 480 | ≥25 |

| ST35 | ≥235 | 340 to 480 | ≥25 |

| ST45 | ≥255 | 410 to 520 | ≥25 |

| ST52/E355 | ≥355 | 490 to 630 | ≥22 |

Advantages of Phosphated Hydraulic Steel Tubes:

Phosphating is to add a phosphate film, a phosphate compound layer, to the seamless hydraulic tubes.

- Improve the adhesion of paint and coating: the phosphate layer can be used as a primer for paint or coating to improve the adhesion of the coating and ensure that the coating is more solid.

- Enhance corrosion resistance: EN1305 DIN2391 phosphated steel tubes can prevent the surface of pipes from rusting due to oxidation or contact with corrosive media.

- Especially in wet, salt spray or other corrosive environments

- Improve wear resistance

Why Seamless Hydraulic Tubes is Cold Drawn or Cold Rolled?

The main purpose of cold drawing or cold rolling is to further improve the precision, strength and surface quality of seamless precision carbon steel hydraulic tubes through plastic deformation process.

Therefore, seamless galvanized steel tubes have higher dimensional accuracy, surface quality and mechanical properties.

Solid seamless precision steel tubes can be better used in hydraulic and pneumatic systems. As well as precision machinery and engineering machinery and other fields.

Application of Precision Seamless Steel Pipes

With advanced technology, seamless precision carbon steel tubes are designed to meet the stringent requirements of a wide range of industries. Superior strength, precision and durability make them a choice you can trust:

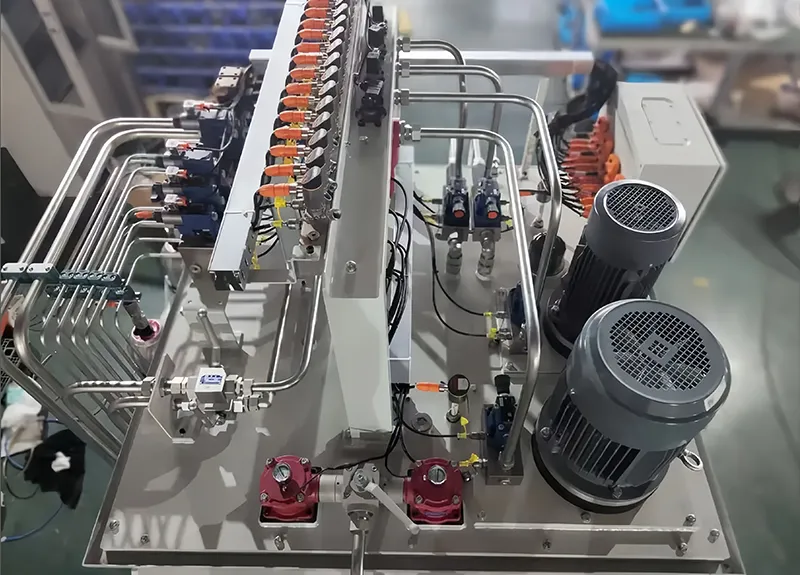

Hydraulic or pneumatic systems: Mainly used in pipelines and booms of construction machinery, agricultural machinery, and industrial equipment.

Automotive industry: As a key component in suspension systems, fuel lines and other precision engineering parts.

Industrial machinery: Provide powerful and precise solutions for fluid delivery and structural support.

Aerospace and defense: Meet stringent performance and safety standards in high-risk environments.

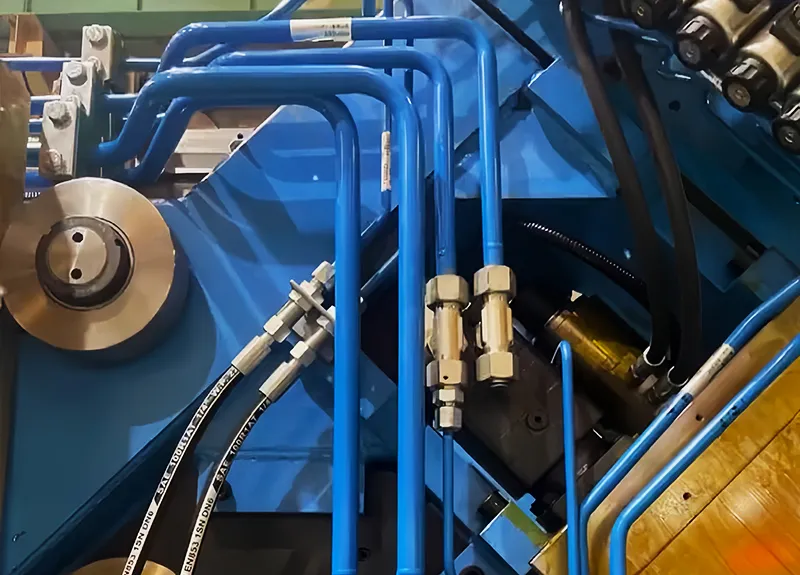

Machinery Boom

Hydraulic System Lines

Hydraulic or Pneumatic System

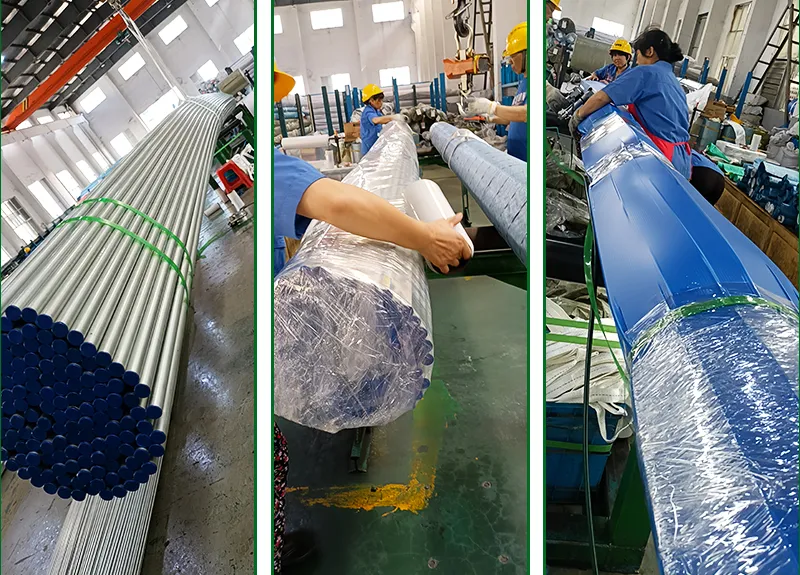

Package & Shipping of Seamless Hydraulic Steel Tubes

All EN1305-1, EN1305-4, DIN2391 cold drawn seamless precision steel pipes are carefully packed to provide maximum anti-collision protection to ensure their intact transportation.

The packaged seamless carbon steel precision hydraulic tubes are packed in wooden boxes or containers. It depends on the quantity of goods.

Packaging for Seamless Hydraulic Tubes

Wooden Box Package

Container Shipping

Factory of Carbon Seamless Steel Tubes

Our factory has more than fifteen years of export experience, has advanced production equipment, and has cooperated with customers in more than forty countries.

Seamless Steel Pipes Workshop

Seamless Precision Steel Tube Factory

Seamless Steel Hydraulic Pipes Factory

Contact Seamless Precision Steel Tubes Experts Directly!

Also you can contact us directly to: [email protected]”